Chief Exec’s report Q1 2021

The first two months of 2021 have been if we are honest, not what we would have hoped for in our cautious state of optimism back in December. Further education in the natural ability of a virus to mutate for maximum effectiveness led us back into strict lockdown, homeschooling for some, and a dent to the confidence that a rollout of not one but two excellent vaccines brought. Add to that our annual shortage of actual daylight along with some proper winter weather and it’s easy to see why it’s been more challenging than ever to stay upbeat.

One reason to do just that was the support extended to the sector by our respective Governments – the UK Government through extension of the furlough scheme allowing companies to offset losses and retain key skills, and equally the Scottish Government encouraging manufacturers to stay in operation whilst others unfortunately were asked to close. This latter support was very welcome and was also more than earned through the hard work and innovation demonstrated by manufacturing companies applying every lesson learned in the use of effective risk assessment and management controls. The net effect of those efforts were the excellent reported levels of compliance from HSE Covid inspections, demonstrating a sector able to rapidly adapt and remain fully in control of a challenging public health issue.

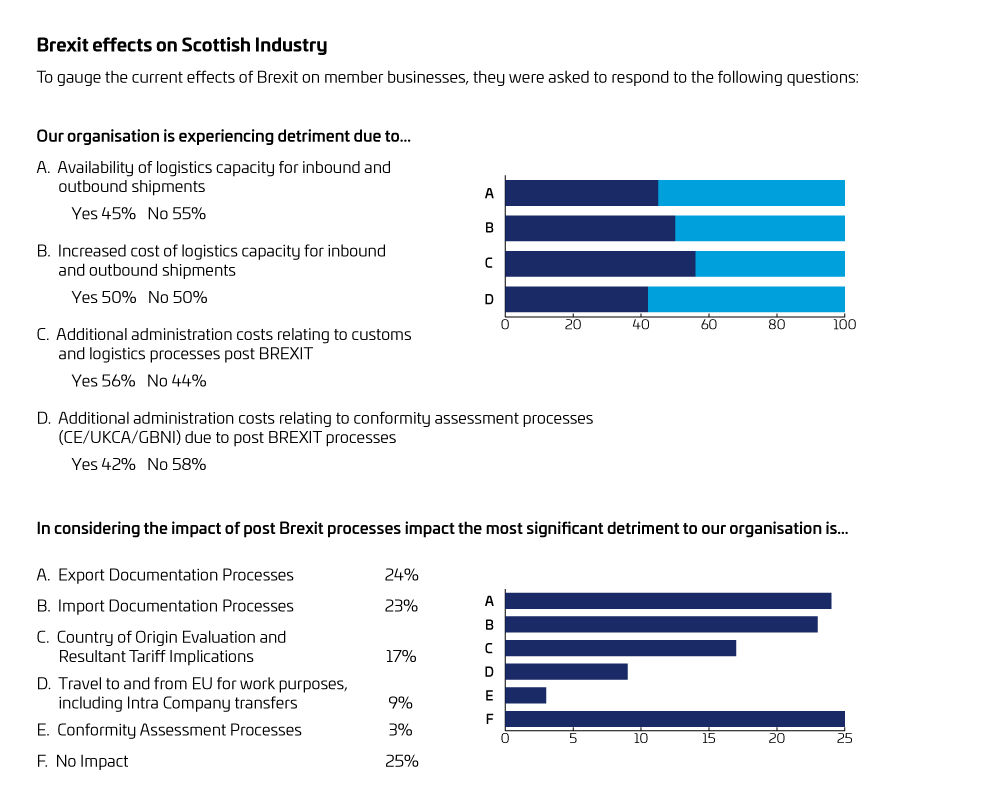

If recognition of our sector’s Covid response is a positive this quarter, then the reality of ending the Brexit transition period has been more than its balance. Even the best prepared companies with solid export and import experience have contacted us to seek direction to advice on complex areas of VAT, duty suspension, conformity assessment, country of origin rules and essential travel to support customers. Some of these rules were only clarified on completion of the UK:EU trade agreement, less than ten days before the end of transition period, and frankly the online guidance tools are not enough to help. One member responding to this survey said the help they needed is “Clear rules and procedures, a helpline of some kind …. as it now feels as though import/export has become a specialised field which makes it impossible for small businesses to manage on their own”.

The impact of this has certainly been increased costs in everything from transit costs to extra administrative burdens, and we have already reported that the major concern is late delivery to customers leading to a potential change to sourcing within the EU. The big question remains: are the issues merely teething problems that will settle down, or is this evidence of more systemic problems with the implemented solutions to Brexit? The answer has to be a mix of the two, as there is no doubt that companies who never thought twice about sending or receiving goods from Europe have been on a steep learning curve, and there will always be room for efficiency improvements. There have also been clear examples that the training, resources and systems have inadequacies that need to be fixed as soon as possible. A final word on Brexit from another member company stated, “Brexit is a significant issue, poorly signposted and businesses (are) left to pick up the burden and the cost”.

One of the more interesting questions of the last quarter has been finding a definition of what ‘green economy’, ‘net zero’ or ‘climate emergency’ skills are? The question was raised as part of Skills Development Scotland’s work to form a Climate Emergency Skills Action Plan (CESAP), and for us it prompted some useful conversations with industry on what this means. After all, the gearbox and generator in a wind turbine are still a gearbox and generator, and a hydrogen fuel cell is for the most part a high-pressure gas system with valves, instrumentation, and pipework. There will be specific product level knowledge needed, but in essence the good news is that the core hands-on skills are nothing new under the sun. Even if you say that for green jobs, enhanced levels of digital skills are key, where in industry wouldn’t say that today? What does seem to stand out from those conversations is that net zero skills will require an understanding of the importance and principles of de-carbonisation, along with a mind-set change to bring adaptability to go quickly, safely, and effectively. Clean technology projects will almost always be investor backed, with clear benchmarks for return on investment, and consequently requiring ever higher levels of cost efficiency and continuous improvement to ensure the project gets off the drawing board to become a reality.

Paul Sheerin

Chief Executive

Scottish Engineering