Author

Neil Tominey, Industrial air quality expert

Zehnder Clean Air Solutions

5 minute read

The invisible threat: Airborne contaminants in the metal industry

In the bustling environments of metalworking shops and factories, the air is often thick with more than just the sounds of productivity. Fumes, metal dust, and oil mist are common by-products of industrial processes, posing significant health risks to workers and visitors alike. These contaminants are not merely an invisible nuisance; they are a tangible danger that can lead to severe respiratory issues, skin problems, and other health hazards. Furthermore, industrial pollution has additional negative effects that you might not have considered. It can damage machinery, increase cleaning efforts, and inflate operational costs.

Why industrial air cleaning?

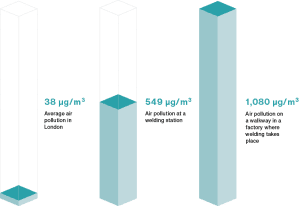

Across Europe, industrial air cleaning is becoming a fast-growing concept as more and more businesses recognise its significant benefits. It’s not just about meeting regulatory requirements – it’s about creating a safer and more productive environment for everyone. Air quality measurements show that air pollution in industrial settings is not only present next to work processes; it migrates throughout the facility. This means that harmful particles can affect all areas, making it crucial to focus on protecting everyone, not only workers but also visitors, office staff, customers and anyone else who may be entering the premises.

What is industrial air cleaning?

You might be thinking, “We’re safe; we have extraction systems or Local Exhaust Ventilation (LEV) in place.” But don’t be misled. While these systems are often mandatory for processes such as welding, there are still not efficient enough to capture all airborne contaminants in your factory. Industrial air cleaning goes beyond LEV systems by capturing the finer particles that escape traditional methods. It’s not a replacement but a complementary solution that ensures comprehensive air purification. Moreover, industrial air cleaning isn’t limited to metalworking. Its applications span various industries, from welding to logistics, food production, and very sensitive environments where a clean room level climate is necessary. Any industry that generates airborne contaminants can benefit from these advanced systems.

The legal requirements for air quality in the workplace

As you will know if you have received a visit from the Health and Safety Executive (HSE) in recent years, air quality in the workplace has become an increasing focus for them. While enforcement of the regulations is a constant activity for them, in recent years they have opted to take a sector specific approach to inspections meaning they will focus heavily for a quarter on a specific topic. Recent examples are the metal working fluid campaign which targeted companies which have CNC milling processes, and the metalworking campaign which targeting businesses which perform significant volumes of welding.

While they will enforce the law relating to specific substances which should be COSHH controlled and fall under the Workplace Exposure Limits (WELS), they will also increasingly push business to find opportunities to ensure that airborne pollutants are reduced to As Low As Reasonably Practicable (ALARP). This is understandable and logical when we consider that specific legislation in this area tends to lag behind both research but also pedagogical information. We only need consider that asbestos was once thought to be a safe and efficient material for use in construction to realise that what we consider today to be benign may someday be considered as totally unacceptable and a serious risk for businesses both from a compliant and liabilities perspective. With that in mind, a prudent approach is to look ahead and ensure that what can be done – within reasonable limits – is done to provide the workforce with clean air.

Leading the change: Air safety champions in Scottish Engineering and Manufacturing

Several members of Scottish Engineering have already installed air cleaning, experiencing first-hand the transformative impact it can have on workplace safety and efficiency. At Zehnder, we have proven that it’s possible to reduce airborne waste by anywhere from 50 – 80 %, depending on the processes and layout of the plant. This early adoption underscores the growing recognition of the importance of clean air in maintaining a safe and productive work environment.

Adding Value While Reducing Costs

A common reaction to the idea of adding additional air cleaning equipment is often ‘good idea but what about the cost?’. Given the current challenges faced by UK industry, it’s a logical response but with the right approach that needn’t be a concern. At Zehnder we have specifically sought to work with our customers to both quantify the costs of poor air quality in the workplace but then also to measure the benefits of clean air.

Take for example a major logistics provider who saved themselves £20k per year on their cleaning costs – that saving was when the cost of air cleaning was taken into account. Also take the automotive parts manufacturer who was able to reduce their rejected products by removing dust from their process leading to an estimated a six-figure saving annually. We have customers who have managed to reduce recruitment and agency costs by offering a better working environment for their staff and so making themselves more attractive to the skilled workers they need not only to attract but also retain for the long term.

Every business is different so it’s impossible to offer a one-size fits all solution which is why we spend time getting to know each workplace on it’s own merits and try to align with the objectives of the management before we begin to recommend the best course of action.

Looking Ahead – Smart Manufacturing

In common with the rest of society, the pressure to develop a more sustainable and efficient future will only increase on industry. The good news is that Zehnder is working to ensure our customers can be at the very forefront of developments as technology becomes ever smarter.

Industrial Internet of Things (IIOT) solutions are becoming ever more common place and these have the potential to be able to react in real time to the working environment without human intervention. In practice this means not only that clean air is constantly being delivered, it also means that energy is only consumed when required. In a recent study carried out by Zehnder with a customer in the Netherlands, a reduction of 60% in energy usage was achieved by enabling the smart functionality in our new generation of air cleaners, the CA Max. Air quality and energy efficiency were monitored via a dashboard offering real-time insights which could then be used to prompt the system to react when high levels of airborne particulate were detected. The air cleaners then increased power until the air quality fell back to within acceptable, pre-set levels and the power was reduced until needed again.

This allied to the potential savings in manufacturing and housekeeping process improvements means that clean air will not be viewed in future as a cost, but rather as an opportunity to refine manufacturing processes, improve quality and to reduce waste.

What we can promise: Clean air will transform your workplace

Are you truly confident that your workplace air is safe for your employees? Are you taking all the necessary steps to protect their health and well-being? The benefits of clean air in industrial settings are profound: better health, increased productivity, regulatory compliance, and a safer environment for all.

We are here to support the members of Scottish Engineering with advice on air quality. If you believe our solutions could add value to your business, we’d be delighted to create a bespoke proposal tailored to your specific needs.

To learn more about how Zehnder Clean Air Solutions can help your company breathe easier, visit our website. Discover how our innovative systems can ensure your facility is a safe, productive, and welcoming environment for everyone.

I’m Neil Tominey, your expert for better workplace air

As the Scotland-based air quality expert for Zehnder Clean Air Solutions, I joined the company at the beginning of this year, and I have to say it has been a breath of fresh air (pardon the pun!).

For the last 10 years, I have worked in technical-based sales roles, and my approach has always been that open and honest communication should be at the heart of any business relationship. Zehnder’s consultative approach to their relationship with customers and their aim to genuinely make the workplace a safer environment for people has seen me settle into the role with ease.

As part of our service, I can visit your site and conduct a free of charge site survey to assess your working environment and offer my expertise on how to improve your air quality. If you would like to have a chat about any concerns or challenges you may have, please feel free to contact me directly.

Neil Tominey

Industrial air quality expert

Zehnder Clean Air Solutions

+44 7900 923848

[email protected]